January 6, 2017

DLM Design completed delivery of the largest project to date in February 2016, a complete stinger load monitoring system for pipe lay stinger designer and manufacturer Antares Energy Solutions Pte, with the Stinger itself being installed onto McDermott’s state of the art DLV2000 pipe lay vessel. DLM Design successfully designed and manufactured the system at their head quarters in Southampton, UK and then travelled to Singapore and Batam, Indonesia for the commissioning.

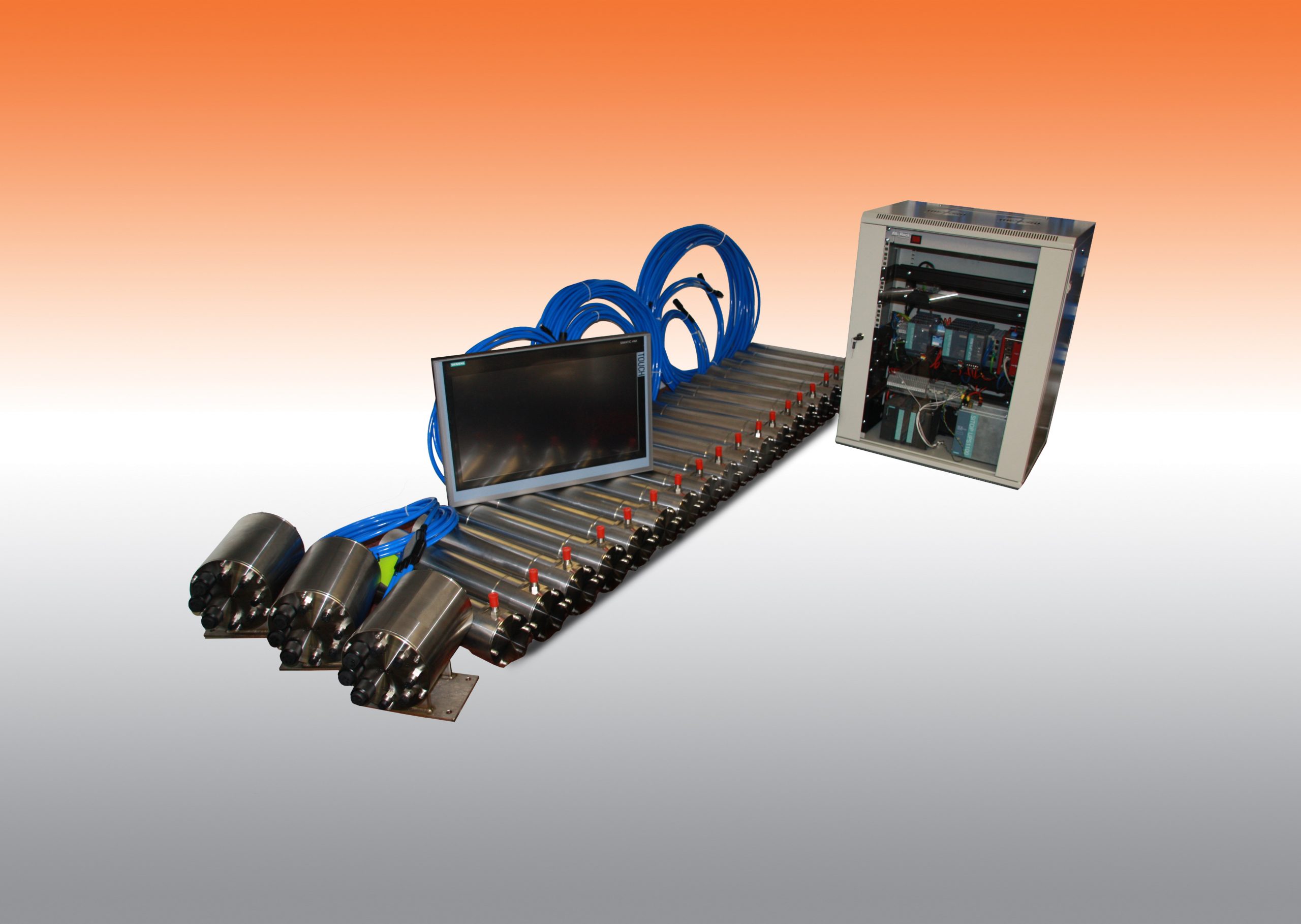

Incorporating 46 of DLM’s unique force magnitude Load Pins, the function of which enables load to be read on multiple different planes around a Load Pin, is unique in the world of load monitoring. The Load Pins monitored pipe forces at each of the fourteen pipe roller boxes and combined with depth sensors at each end of the three articulated stinger sections, along with an inclinometer in order to determine depth of stinger sections and angle of the stinger during pipe-lay operations. DLM’s Design Engineering team employed the use of various industrial control technologies including Profinet, Profibus, RS485 Modbus and Modbus TCP. A Siemens S7-300 PLC and HMI display were implemented to integrate and display the sensors values, with the HMI screen allowing for interrogation of each Load Cell and Sensor, configuration of alarm reporting, historical data logging and many other features.

The biggest challenge was to enable the 46 Load Cells to communicate down a single pair of twisted pair cabling, this was achieved by using RS485 Modbus to sequentially communicate with each Load Cell. Using this method also allowed for enhanced diagnostics and alarming as it was possible to tell exactly which Load Cell is outputting a certain value.

In order to ensure a robust solution was provided the system incorporates full redundancy to allow operations to continue in the event of damage. This included a redundant power supply and a separate standalone UPS allowing the system to continue running and eliminate data loss in the event of total power failure. The system operates through RS485 twisted pair, however in order to protect against data loss should a signal cable be damaged, the system will automatically switch over to a fiber optic redundant loop without loss of signal.